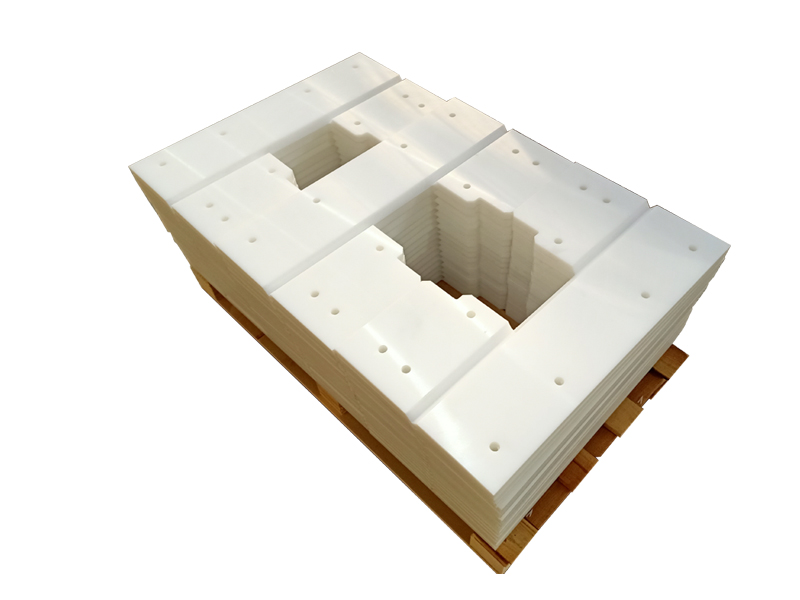

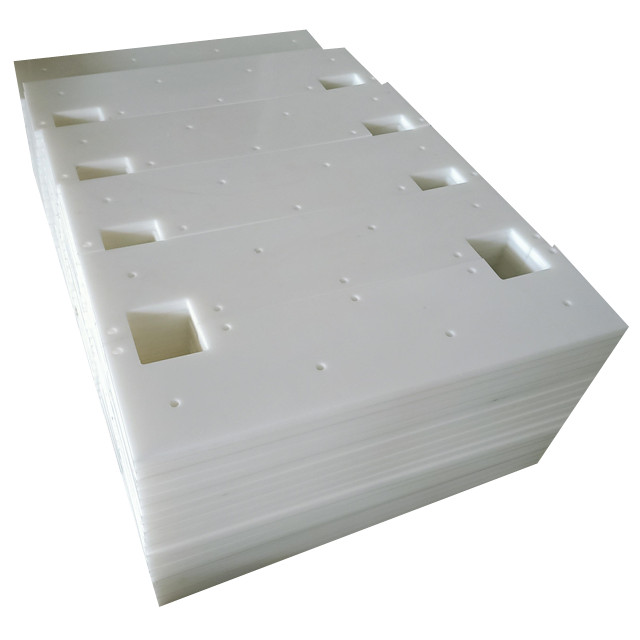

Wear Resistant UHMWPE Scraper Blade for Drag Chain Conveyor CNC processing plastic parts

The scraper product is made of ultra-high molecular weight polyethylene (UHMWPE) due to its extremely high melt viscosity, it is not liquid even when heated to its crystalline melting point, and this immobility is due to its ultra-long single molecule The chain is highly tangled. In layman's terms, it is like a pile of hemp ropes. Low molecular weight polyethylene such as polyethylene wax is like 10,000 one-meter-long hemp ropes that are entangled together and can be easily separated; ordinary polyethylene products are like a thousand ten-meter ropes. The long hemp ropes are entangled together, and it is not easy to separate them, but they can be separated with a little effort; and ultra-high molecular weight polyethylene (UHMWPE) is like a hundred hemp ropes 100 meters long. Together, it can be difficult to separate them even with a lot of effort. Because of this, ultra-high molecular weight polyethylene (UHMWPE) has many extraordinary properties.

The scraper made of UHMWPE has the following characteristics:

1. Non-stick material:

The surface adsorption force is very weak, its anti-adhesion ability is second only to PTFE, the water absorption rate is almost zero, only 1% of PA6, coal dust, wet soil, laterite, and other highly viscous goods even if the humidity is high, It will not stick to it, and the sliding speed of the material has nothing to do with the humidity factor.

2. Wear resistance:

The wear resistance of polyethylene liner ranks first among engineering plastics, and the wear resistance of polyethylene liner is higher than that of many metal materials (such as carbon steel, stainless steel, bronze, etc.). The abrasion index of mortar is only 1/5 of PA66, 1/10 of HDPE and PVC; compared with metal, it is 1/7 of carbon steel and 1/27 of brass.

3. Self-lubricating

The coefficient of static friction is 0.07, and the self-lubricating property is good, second only to polytetrachloroethylene (PTFE) under the condition of no lubricant; the lubricity is better than that of steel and brass with lubricating oil. It is an ideal lining, the friction part of the equipment, in addition to improving the wear-resistant life, it can also receive energy saving effect.

4. Corrosion resistance:

Polyethylene liner is not corroded in alkaline solution, stable in 75% concentrated sulfuric acid and 20% nitric acid, and it is also stable in seawater and liquid detergents. To

5. Impact resistance:

The polyethylene liner has a large molecular weight and tight chemical bonds. Therefore, it has strong impact resistance and will not break. The impact strength is 10 times that of nylon 66, 20 times that of polyvinyl chloride, and 8 times that of PTFE; the impact strength is about 2 times that of impact-resistant PC, 5 times that of ABS, and more than 10 times that of POM and PBTP. Especially in the low temperature environment, its impact strength reaches a high value, and its flexibility can provide a very safe and reliable guarantee for the conveying system. To

6. Low temperature resistance:

Polyethylene car sheet is a material with excellent toughness, and its low temperature resistance is also very good. It still has a certain degree of ductility at a low temperature of -269 °C, and there is no sign of embrittlement.

7. Hygienic and non-toxic:

It is tasteless, non-toxic, odorless, non-corrosive, and has physiological inertia and physiological adaptability. nice

8. Light weight:

The density of UHMWPE is 0.93-.97, which is the lowest density among many materials, and the lightest and the lightest engineering plastics.

If you want to some information you can check our website https://abosnplastic.en.made-in-china.com/

Contact us

E-mail:fiona@dzabosn.com

Whatsapp:+86 175 5341 8926

Phone:+86 175 5341 8926